Company introduction

Hannai Fiberglass Company is a leading global manufacturer and supplier of fiberglass, providing professional product customization and complete sets of fiberglass technology solutions. Compliant with international standards, after nearly 30 years of unremitting efforts, we currently have four production factories, 22 advanced fully automatic microcomputer intelligent control production lines, and over 180 models of fiberglass series products, which are exported to dozens of countries and regions.

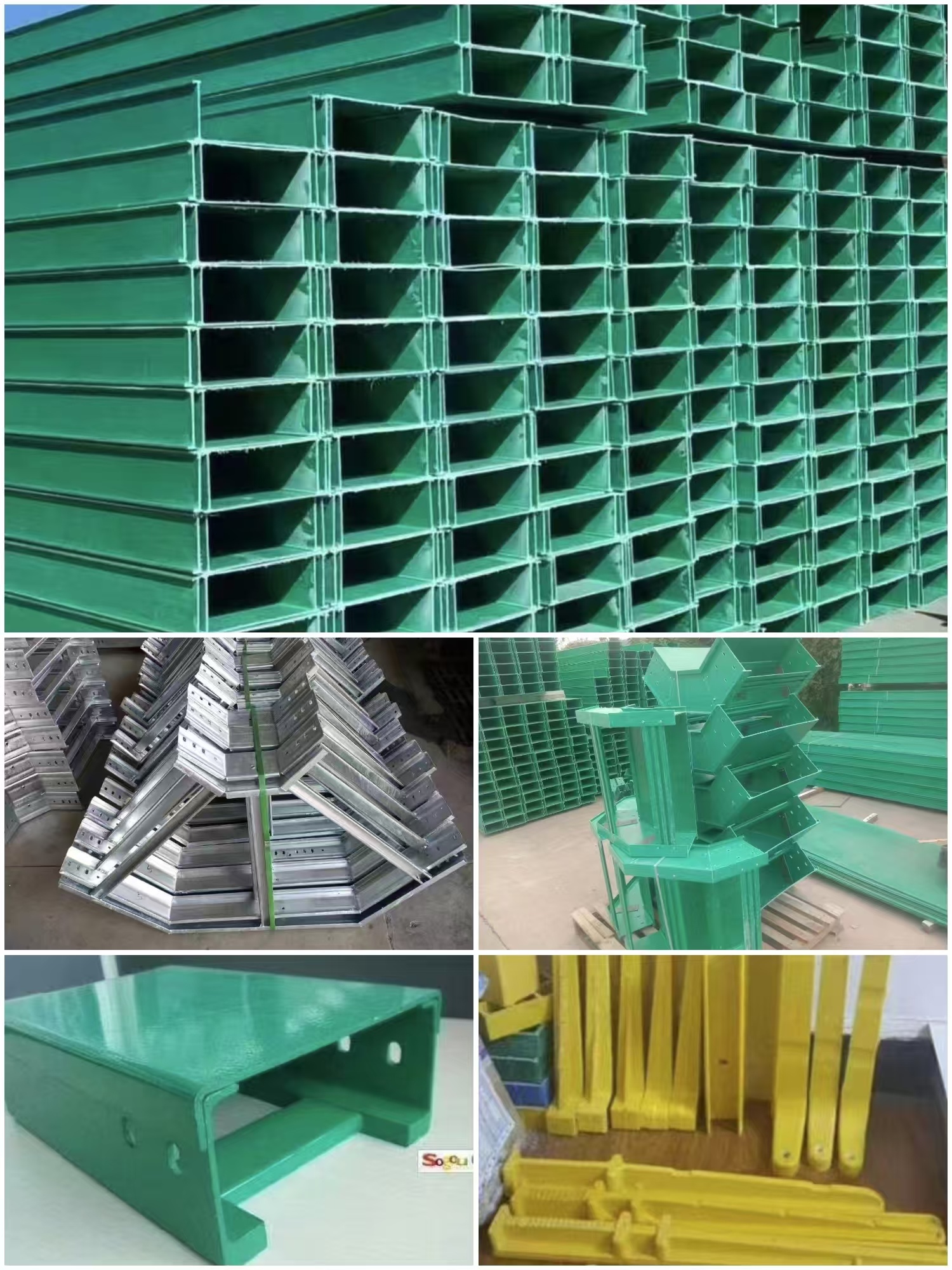

Fiberglass/Fiberglass Cable Tray

Fiberglass cable tray, also known as GRP or FRP cable tray. Fiberglass cable trays are made of resin impregnated fiber yarns that are alkali free, untwisted, and wax free. They are extruded at high temperatures and produced using continuous mechanized production processes. Fiberglass cable trays are lighter in weight and have better corrosion resistance and flame retardancy than ordinary steel cable trays. They are widely used in industries such as petroleum, chemical, power, light industry, television, and telecommunications. Hannai Company provides customers with a complete set of fiberglass cable tray solutions

Resin selection table

| Resin type | Describe | Application |

| Vinyl ester | Excellent corrosion resistance performance | Corrosion is a serious environmental issue. |

| Flame retardant vinyl ester | Excellent corrosion resistance and flame retardancy | An environment with strong corrosiveness and good flame retardancy requirements |

| Isophthalic acid polyester | Industrial grade corrosion resistance performance | Used in environments with moderate or lower concentrations of inorganic acids, alkalis, etc. |

| Flame retardant isophthalic acid polyester | Industrial grade corrosion resistance and flame retardancy | Used in the field of inorganic acids with low concentration and high requirements for flame retardancy |

| Ortho phenylpolyester | Moderate corrosion resistance | Suitable for environments that require waterproof and weather resistant solutions. |

Advantages of FRP/GRP cable tray

1. Corrosion resistance. FRP materials have good corrosion resistance, aging resistance, insulation, non-conductive, and anti-static properties. Very suitable for environments with severe corrosion.

2. Resistant to ultraviolet radiation, electricity, salt water, and chemicals.

3. High temperature resistance, fast heat dissipation, excellent temperature resistance performance. The fiberglass flame-retardant cord reel is made of flame-retardant materials and can be self extinguished.

4. High strength and rigidity, FRP cable tray has high strength and can withstand high loads of cables.

5. FRP cable trays with covers can protect cables from falling objects, dust, and water damage.

6. Stable size, no shrinkage, no expansion, long service life, no deformation, no cracks, no moisture absorption, no halogen retreat, high quality and safety.

7. Lighter and easier to operate, FRP cable trays are 40% lighter than stainless steel cable trays. They are easy to cut and install with fasteners.

8. There are multiple colors to choose from (Green, red, gray, etc.).

9. It has the advantages of universal power cycle, practical installation, and moderate price, and has been widely used.

There are many applications in the chlor alkali market, paper industry, potassium sulfate plant food sector, acid regeneration, acid washing market, and chemical fiber industry.

Glass fiber reinforced plastic/FRP or glass reinforced plastic/GRP cable tray specifications

General specifications, thickness, and reference weight for perforated/slotted fiberglass cable tray systems

| Specifications(mm) | Thickness of groove/cover(mm) | Weight (kg) | Specifications(mm) | Thickness of groove/cover(mm) | Weight (kg) |

| 50*50 | 2.7/2.7 | 1.31 | 300*100 | 3.0/3.0 | 4.8 |

| 100*50 | 2.8/2.8 | 1.85 | 300*150 | 3.5/3.0 | 5.7 |

| 100*100 | 2.9/2.8 | 2.4 | 300*200 | 3.5/3.0 | 6.5 |

| 150*100 | 3.0/2.8 | 2.9 | 400*100 | 4.0/3 | 7.1 |

| 200*100 | 3.0/2.8 | 4.1 | 400*150 | 4.1/3.0 | 7.8 |

| 200*150 | 3.0/2.8 | 4.8 | 500*200 | 4.5/4.5/3.6 | 12.1 |

| 200*200 | 3.5/2.8 | 5.2 | 600*150 | 4.6/4.8/4.0 | 12.6 |

| 250*100 | 3.0/3.0 | 4.5 | 600*200 | 5.0/4.0 | 14.2 |

| 250*150 | 3.5/3.0 | 5.5 | 800*200 | 5.0/4.5 | 18 |

General specification for thickness and reference weight of ladder type fiberglass bridge channel system

| Specifications(mm) | Thickness of groove/cover(mm) | Weight (kg) | Specifications(mm) | Thickness of groove/cover(mm) | Weight (kg) |

| 200*100 | 4.0/3.0 | 4.1 | 400*150 | 4.0/3.0 | 6.6 |

| 200*150 | 4.0/3.0 | 4.8 | 400*200 | 4.0/3.0 | 7.7 |

| 300*100 | 4.0/3.0 | 5.1 | 500*150 | 4.0/4.0 | 9.1 |

| 300*150 | 4.0/3.0 | 5.7 | 500*200 | 4.0/3.0 | 10.1 |

| 400*100 | 4.0/3.0 | 6 | 600*150 | 4.0/4.0 | 9.6 |

| 500*100 | 4.0/4.0 | 8.5 | 800*150 | 4.0/4.5 | 13.1 |

| 600*100 | 4.0/4.0 | 9 | 1000*150 | 4.0/4.5 | 11.2 |

| 800*100 | 4.0/4.5 | 10.4 | 200*200 | 4.0/3.0 | 5.9 |

| 1000*100 | 4.0/4.5 | 12.5 | 300*200 | 4.0/3.0 | 6.8 |

Color: Grey, blue, yellow, red, other custom colors

The length can be customized according to customer needs

Product Display

Tag:

Cable tray

Applicable model:

E-mail:hnfrp@hannaifrp.com

Hotline:+86-13803189948

Product Classification:

Get Quote

* Note: We will contact you within one working day. Please be sure to fill in the information accurately and keep the communication open, we will get in touch with you as soon as possible

Related Products

SMC/FRP/GRP panel water tanks are an ideal way to store water.

Chemical acid-base storage tank

Fiberglass chemical storage tanks (also known as FRP chemical storage tanks) are manufactured using filament winding technology.

Hannai Company is a professional manufacturer and supplier of FRP vertical storage tanks, which are made by mechanically winding fiber-reinforced resin

The horizontal fiberglass water tank adopts high tension, multi-layer, multi angle, and wrapped around the head.